SP Wellbore Cleanup and Displacement System

Provide reliable solution for deepwater wells, deep wells, and deviated wells

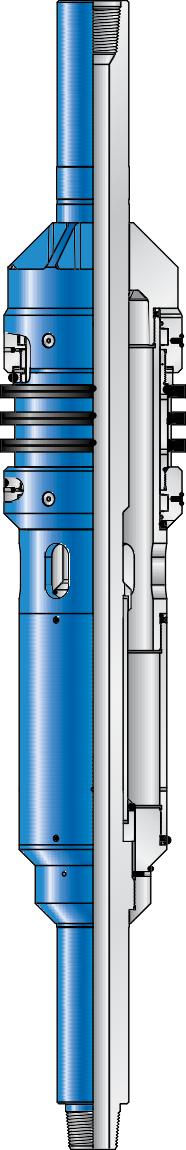

The award-winning SP wellbore cleanup and displacement system is a durable system for deep, deviated and extended-reach well applications. This system provides reliable and effective wellbore cleaning and significantly mitigates completion and production risks with exceptional features including high tensile and torque ratings, high allowable rotation speed, non-rotating design, and high circulation areas.

The SP wellbore cleanup and displacement system combines several high-performance tools to clean interior casing walls and blowout preventers, scrape and brush casing/liner inside diameters (IDs), filter downhole fluids, seek out and collect debris, and provide an effective means for fluid displacement. These tools can be run together as integral parts of a complete wellbore cleaning system or individually to perform specific functions.

In addition to the features above, the deep well riser brush and boot basket has no welding in its structure. This simplifies the deepwater inspection and improves operation reliability. The tool has magnets attached to the mandrel to provide more effective metal debris collecting inside the boot basket.

The casing scraper and brush provide 360° contact with the casing/liner ID. The casing scraper uses both ends and sides of the scraper blades, giving dual cleaning effect. The helical shape of the scraper blades and brush blocks significantly increases annular flow area so that fluid can be circulated at high flow rates. The non-rotating design eliminates the risk of damaging or wearing casing when rotating drillstring.

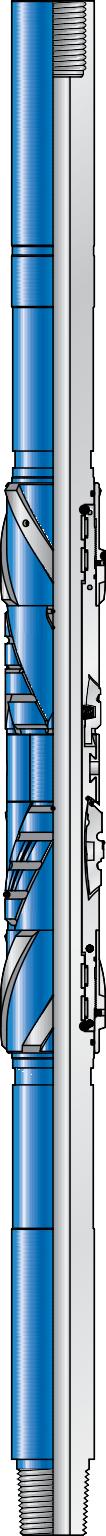

The downhole magnet inherits the simplicity and robustness of the field-proven Grabitz magnet, but advances the Grabitz magnet with many times the metal debris collecting capability.

The multitask wellbore filter features slidable brush design, providing an effective method to divert flow and collect debris. The patent-pending debris-removing window allows for simple debris-removal operation.

Specifications

Tensile rating: higher than the tensile rating of tool joints

Torque rating: higher than the torque rating of tool joints

Allowable rotation speed: 150 rpm

Applications

Deepwater wells

Deep wells

Deviated wells

Extended-reach wells

Wells with high dogleg severity

Features and Benefits

Modular design

Allows a wide range of adaptability for various well circumstances

One-piece mandrel design with higher-than-tool- joints tensile and torque ratings

Provides a reliable and effective tool to clean wellbores and

Significantly mitigates completion and production risks and costs

Non-rotating scrapers, brushes, and stabilizers

Effectively cleans well without damaging or wearing casing wall

Highest allowable rotation speed of 150 rpm

Effectively cleans the wells without damaging or wearing any casings or risers

Large circulation areas

Improves circulation and displacement efficiency

Advanced debris/metal debris carrying capability

Improves cleaning efficiency